Hydraulic crushing hammers have become an important working tool for hydraulic excavators, and some people have installed hydraulic crushing hammers on two busy or wheeled loaders for crushing operations. This makes crushing hammers widely used.

1. Mining: mountaineering, mining, lattice crushing, secondary crushing

2. Metallurgy: ladle, slag cleaning, furnace body demolition, equipment foundation demolition

3. Railway: mountain excavation, tunnel excavation, road and bridge demolition, subgrade compaction

4. Highway: highway repair, cement pavement crushing, foundation excavation

5. Municipal gardens: concrete crushing, water, electricity, gas engineering construction, old city reconstruction

6. Buildings: demolition of old buildings, crushing of reinforced concrete

7. Ship: hull clam removal and rust removal

8. Others: ice breaking, frozen soil breaking, sand type vibration

Although the application range is very wide, the market share of domestic manufacturers is still very low, and most of the market is occupied by products from Japan, South Korea, and Germany. Therefore, our domestic enterprises should also seize the market opportunities to develop, carefully manufacture, continuously innovate, seize the domestic market, and export abroad.

Lingdong Hydraulic Tiltrotator Ecosystem

The range of attachments compatible with Lingdong Hydraulic Tiltrotators, especially high-end models that require hydraulic circuit integration, has always been one of the main product lines of Lingdong Intelligent Equipment Co., Ltd. The company has the capability to design and produce a full range of excavator attachments, from hydraulic breakers to multi-functional buckets, grapples, vibrating rammers, fork heads, sweepers, milling machines, and dozens of other products. These attachments are extensively used in various construction sectors, including municipal and road engineering, railways, river management, infrastructure, and landscaping.

Compared to world-renowned high-end hydraulic tiltrotator companies, Lingdong Intelligent leverages the production capacity advantages of the Yantai excavator industry chain. This enables us to meet the high-volume, customized production demands for tiltrotators and related attachments. Moreover, Lingdong’s modular configuration and design capabilities allow major construction machinery brands to efficiently control the cost of mass-producing attachments.

Lingdong’s commitment to providing high-quality hydraulic wrist solutions, rotators, and heavy machinery accessories ensures that our products are optimized for performance, durability, and efficiency in a variety of construction applications. As a leading player in the tiltrotator market, Lingdong is dedicated to advancing the development of the hydraulic equipment industry with innovation and excellence.

Working Principle of Lingdong Hydraulic Tiltrotator for Complex Angles

The hydraulic tiltrotator allows for operations in more complex environments by adding 360° rotation and ±45° tilt axis movement on top of the traditional boom and bucket movements of excavators. This enhanced functionality makes Lingdong hydraulic tiltrotators particularly effective for construction scenarios that require working along parallel paths, in narrow and complex municipal areas, and in other challenging conditions. The ability to achieve intricate working angles results in significantly higher operational efficiency.

Lingdong tiltrotators are ideal for applications in municipal pipeline construction, landscaping, road, tunnel, and bridge construction, building renovations, and port loading and unloading operations. They transform traditional excavators into multifunctional machines capable of performing a wider range of tasks in various construction and heavy machinery fields. The integration of the hydraulic wrist and rotator functionalities enables excavators to achieve enhanced flexibility and adaptability, making them a valuable tool for any construction project.

Lingdong’s hydraulic tiltrotators are designed to upgrade conventional excavators, equipping them with advanced capabilities to handle complex and demanding work environments with greater precision and productivity.

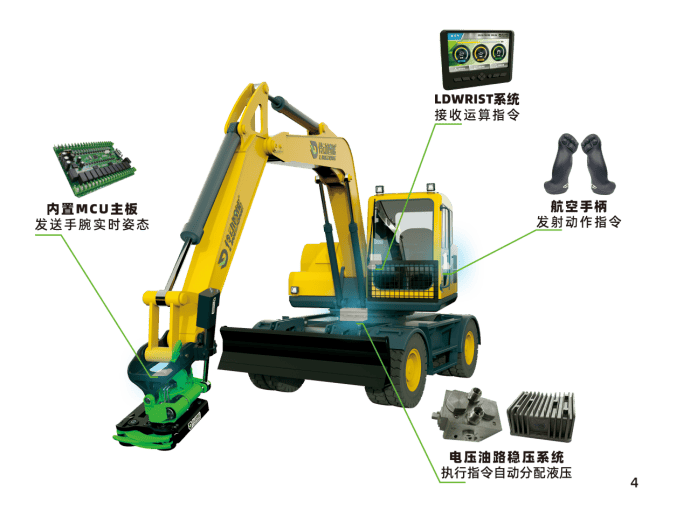

Lingdong Hydraulic Tiltrotator Digital Intelligent Control System

With the addition of two-axis movements, the hydraulic oil flow throughout the entire excavator must be re-planned and redistributed through an optimized hydraulic circuit system. The increased number of complex axial movements requires real-time positional information from the tiltrotator, which is processed by the LD-WRIST system to adapt the movements into simple joystick operations.

Therefore, the Lingdong hydraulic tiltrotator is not merely a simple attachment for the front end of an excavator, but a comprehensive operating system that includes a complete vehicle hydraulic oil redistribution system, a position and attitude sensing system, and a handle action command system. All these elements are integrated and processed by the central LD-WRIST command and computation system.

Lingdong’s hydraulic tiltrotators offer advanced hydraulic control and intuitive operation, making them highly effective for various construction tasks. By optimizing excavators with a smart control system, Lingdong ensures precise and efficient operations in demanding construction environments. This digital intelligent control system upgrades traditional heavy machinery and expands their capabilities, providing a significant advantage in modern construction projects.

Optional LDS2.0 Oil-Electric Automatic Conduction Function

The Lingdong hydraulic tiltrotator offers an optional LD2.0 ultra-thin quick oil-electric conduction function, which enables fast and automatic connection between the hydraulic tiltrotator and hydraulic attachments without the need to plug and unplug hydraulic hoses and electrical harnesses. This feature allows for rapid switching of attachments during construction tasks. Alternatively, users can opt for manual hydraulic and electrical quick couplings to control costs.

For example, an automatic compactor equipped with hydraulic conduction functionality can connect seamlessly with a hydraulic tiltrotator that has the conduction feature. This automatic connection of hydraulic lines and signal transmission significantly reduces the time needed to attach hydraulic tools, allowing for faster and more efficient execution of construction work.

Lingdong’s advanced tiltrotator and hydraulic tiltrotator technology enhances the versatility and efficiency of heavy machinery by enabling quick and automated attachment changes, optimizing performance in various construction environments.